RẤT RẤT

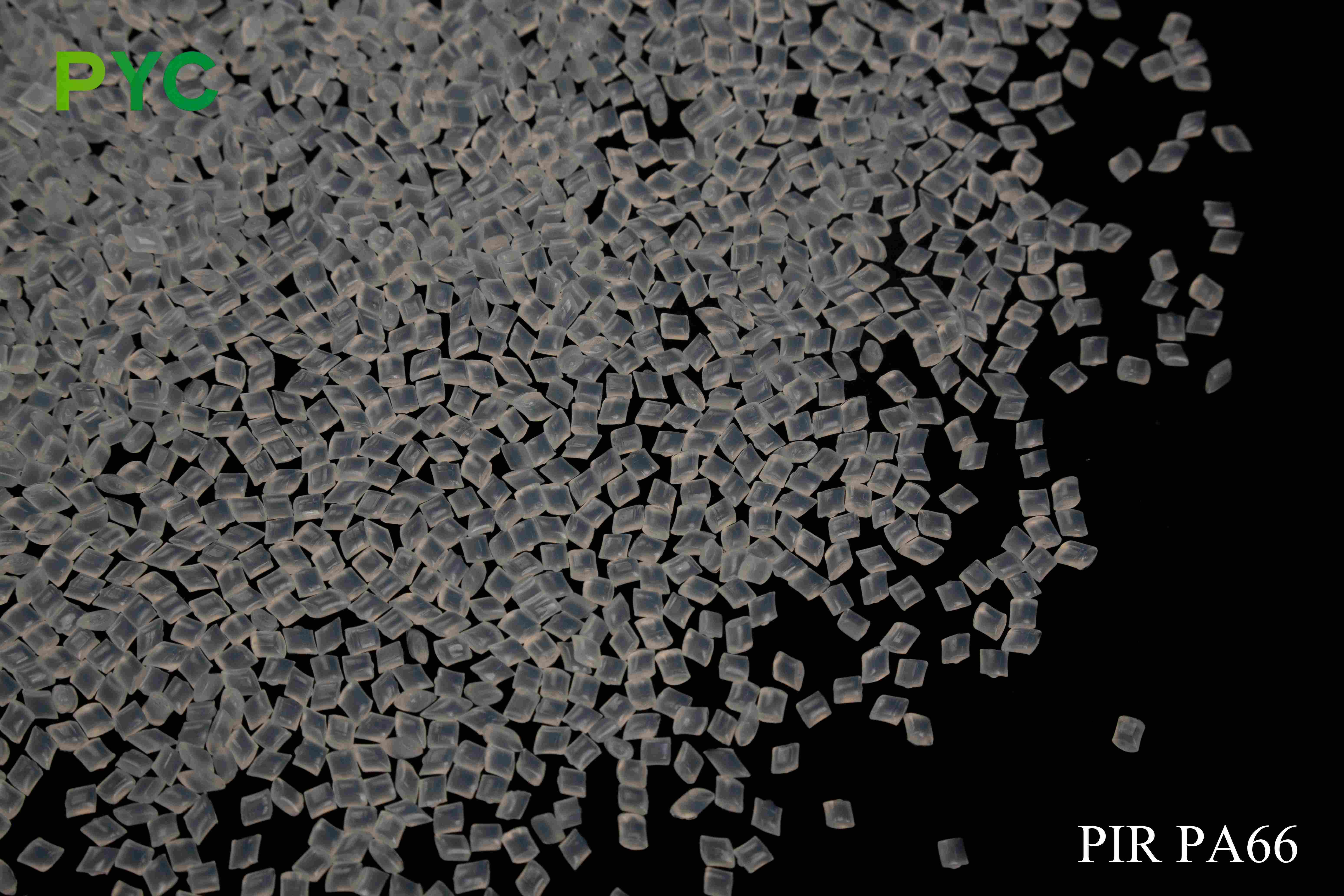

PIR PA (Polyamide tái chế sau công nghiệp) - Polyamide tái chế sau công nghiệp

PIR PA là một loại nhựa thân thiện với môi trường được sản xuất bằng cách tái chế vật liệu polyamide (PA, thường được gọi là nylon) thải công nghiệp. Do có đặc tính cơ học tuyệt vời, khả năng chống mài mòn và độ ổn định nhiệt tốt, vật liệu polyamide được sử dụng rộng rãi trong nhiều ngành công nghiệp như ô tô, điện tử, dệt may và máy móc. Bằng cách tái chế vật liệu polyamide thải trong sản xuất (như phế thải góc, chất thải sản xuất, v.v.), PIR PA không chỉ làm giảm lượng phát thải chất thải nhựa mà còn cung cấp cho các doanh nghiệp các giải pháp phát triển bền vững.

Product Details

1. High-quality recycled feedstock sources

The recycled feedstock for PIR PA comes mainly from waste polyamide materials from industrial production, including:

Production waste: e.g. polyamide fibers, injection molding parts waste, industrial trimmings, etc.

Waste plastic products: e.g. waste nylon shells, parts, etc.

Waste plastic parts: such as discarded car parts, electronic product shells, etc.

These waste materials are screened, cleaned and pulverized, and then converted into high-quality PIR PA raw materials to ensure their environmental friendliness and stable performance.

2. Strict quality control

PIR PA undergoes strict quality control during the production process to ensure the performance and stability of each batch of material. Testing in a variety of areas, such as tensile strength, impact toughness, water absorption, etc., ensures that the material meets industrial standards and is able to meet the needs of different fields.

3. Excellent performance

Abrasion resistance: PIR PA has very good abrasion resistance and is suitable for applications that require long term abrasion resistance, such as automotive parts, mechanical parts, etc.

Excellent Mechanical Strength: PIR PA has high tensile strength and rigidity and is able to withstand large loads and pressures.

Good thermal stability: PIR PA maintains stable performance at higher temperatures, making it suitable for use in high-temperature environments.

Chemical resistance: PIR PA is highly resistant to oils, solvents and other chemicals.

4. Environmental protection and sustainability

By recycling waste polyamide materials, PIR PA reduces the need for new raw materials and effectively lowers plastic waste emissions. The recycling process not only reduces energy consumption, but also reduces the carbon footprint, making it an ideal material for companies looking to green their production and promote sustainable development.

5. Cost-effectiveness

Since PIR PA is made from recycled materials, its production costs are lower than those of brand new polyamide materials, which not only reduces material procurement costs for companies, but also offers more competitive pricing, which helps to improve their competitiveness in the marketplace.

Application area

Automotive industry: PIR PA is widely used in automotive parts, automotive interiors, engine parts, etc., with excellent wear resistance and mechanical strength, it can work stably in harsh environments for a long time.

Textile industry: PIR PA is used in the textile industry as a nylon fiber in carpets, ropes, fabrics, etc., with good strength and durability.

Electronic industry: Used in the production of electronic product shells, plugs, connectors, etc., with good thermal stability and chemical resistance.

Machinery industry: Widely used in mechanical parts, gears, bearings, etc., to ensure high wear resistance and low friction characteristics in long-term use.

Product advantages

High wear resistance: PIR PA is suitable for use in scenes that require long-term wear resistance, such as automotive parts, industrial parts, etc.

Good mechanical strength: PIR PA has good rigidity while maintaining strength and is suitable for applications carrying high pressure.

Environmental protection: PIR PA is produced from recycled materials, which reduces plastic waste and meets the requirements of sustainable development.

Cost-effectiveness: Using PIR PA as a raw material, the production cost is relatively low, providing an economical solution for enterprises.

Excellent thermal stability: PIR PA can also maintain stable performance under high temperature environment, suitable for high temperature applications.

Production and technical advantages

Advanced recycling technology: The recycling process of PIR PA uses advanced technology to ensure the stable quality and performance of recycled materials.

A variety of processing methods: PIR PA can be processed by injection molding, extrusion and other processing methods to adapt to different types of product needs.

Excellent processing performance: PIR PA shows good fluidity and processing adaptability in the processing process to meet the needs of precision processing.